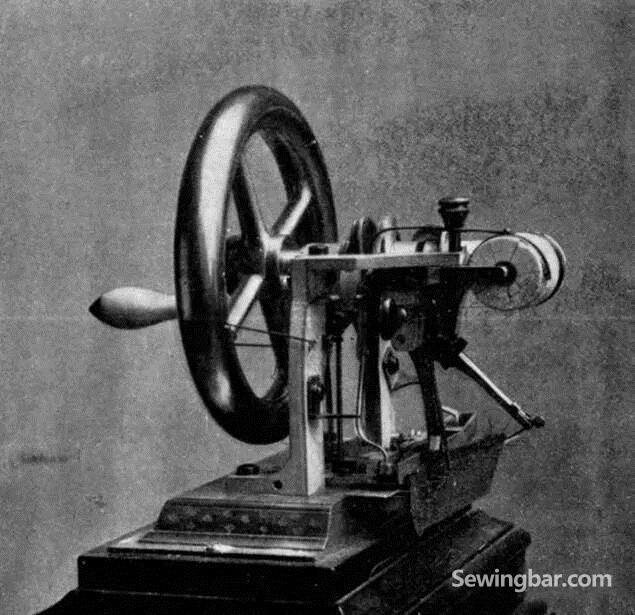

- Universal sewing machine

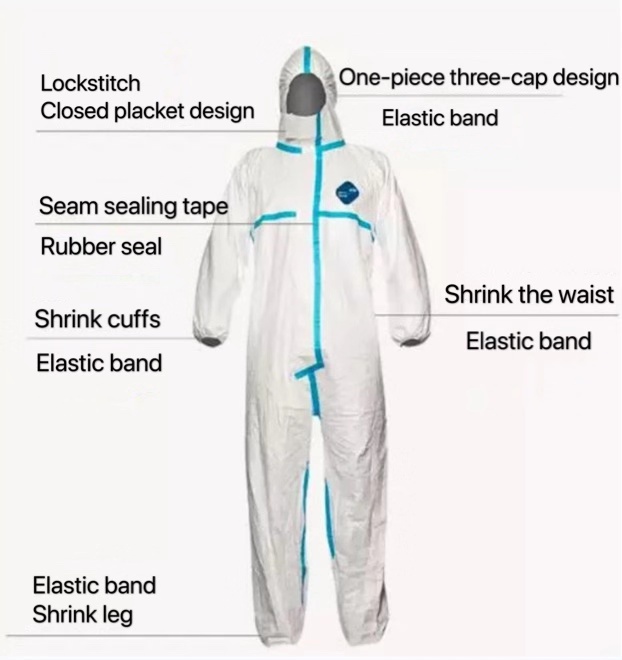

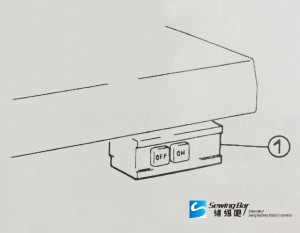

①, industrial sewing machines are widely used in apparel production, mainly for flat seams. In recent years, industrial sewing machine has been developing toward the high-speed and computerized direction, with speed from 3000r / min. up to 5000 ~ 6000r / min.; besides general purposes, industrial sewing machines also have automatic reversing, automatic thread trimming, automatic thread wiping, automatic presser foot lifting, automatic needle position up and down controlling, automatic needle stopping functions and a variety of protection features.

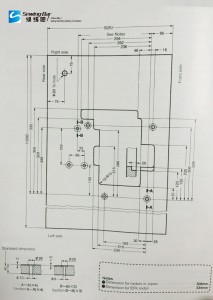

ZJ9700DDI-4 Direct-drive integrated computerized high-speed lockstitch sewing machine with auto-trimmer and auto foot lift

Features:

- Computer controlled integrated high-speed direct-drive sewing machines can be used when it is plugged in electricity, eliminating various plug confusion and installation problems;

- With automatic thread trimming, automatic needle positioning, automatic stitch amount setting, automatic thread wiping and many other sewing modes;

- Excellent feeding mechanism, greatly improving production efficiency;

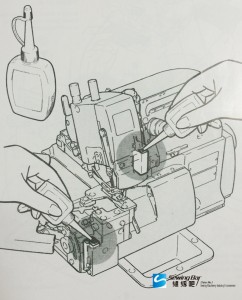

- Built-in thread winder has nice appearance and easy operation advantages;

- Low noise, environment-friendly

ZJ777T-D Direct drive high-speed computerized lockstitch sewing machine with edge cutter

Features: suitable for sewing shirts, suits or similar garment, especially its collars, front opening, etc. The unique feeding mechanism reduces the difference in stitch length between forward and reverse feed to the minimum. The side cutting device can make the sewing and trimming process simultaneously and improves work efficiency.

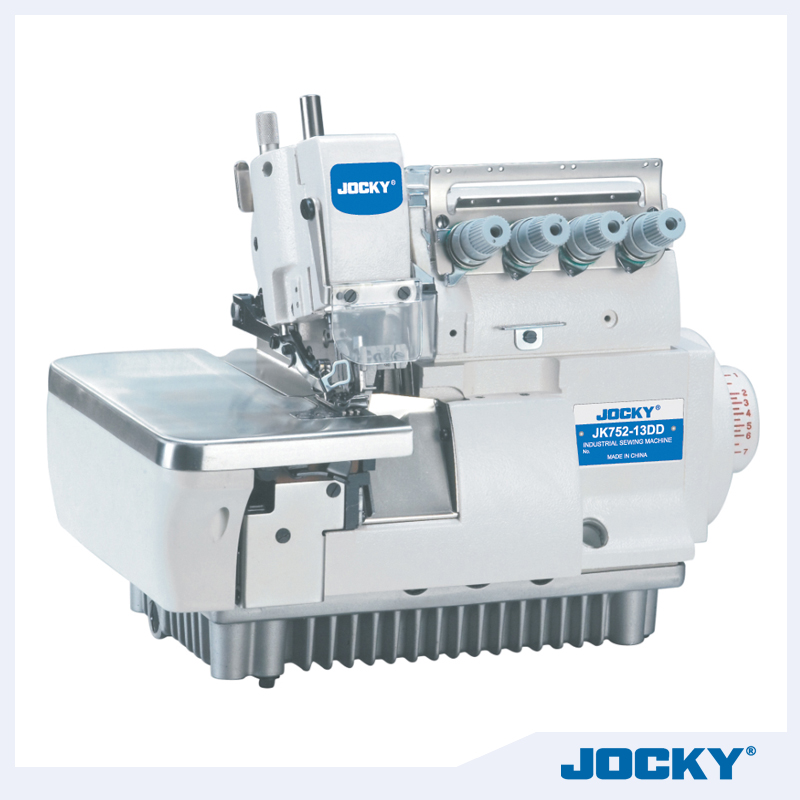

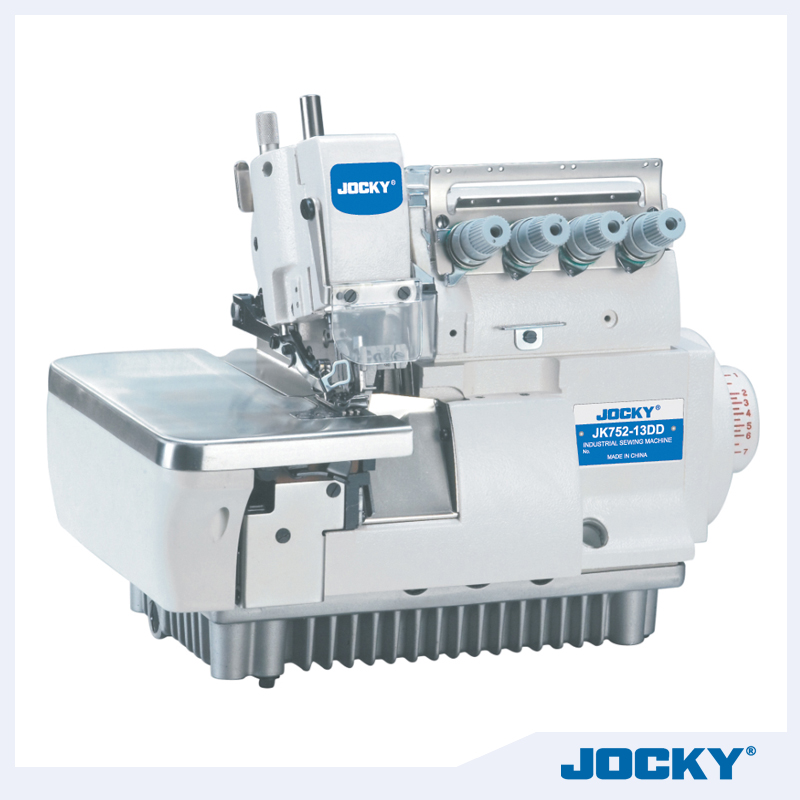

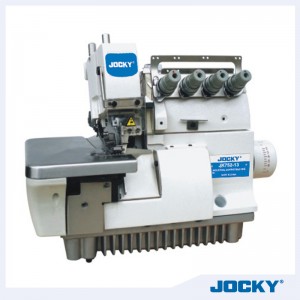

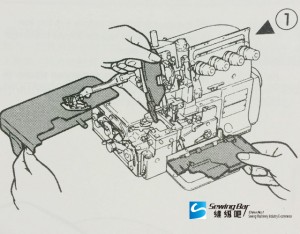

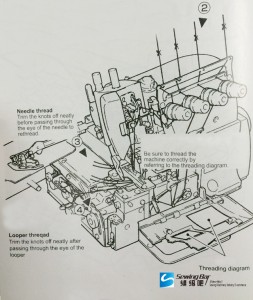

② Overlock sewing machines can be divided into 3 thread, 4 thread and 5 thread overlock sewing machines. 3 thread overlock sewing machines and 5 thread overlock sewing machines have wide applications.

MX5214DD-EUT Direct drive super high speed computerized overlock sewing machine with auto trimmer

Features:

This series has the maximum sewing speed up to 7000 rpm;

Automatic presser foot; installing suction and cutting device;

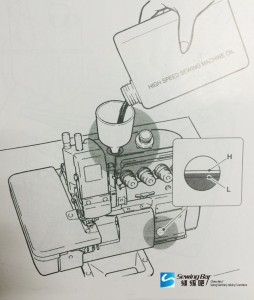

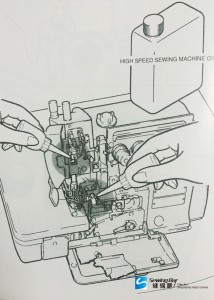

Adopting computerized built-in direct-drive servo motor, saving about 60% of electricity; Adding oil absorbing device in needle bar and rocking parts to prevent oil spills;

Single needle bar support structure, easy to achieve high-speed operation;

Enclosed needle bar mechanism prevents dust inhalation and abrasion and oil leakage occurrence of needle bar;

Installation of oil filter to improve oil cleanliness, to ensure high-speed operation; Maximizing the operating space, making the operation more comfortable and convenient and ensuring beautiful sewing stitches

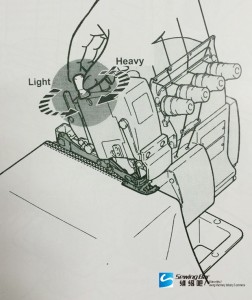

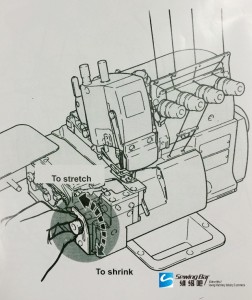

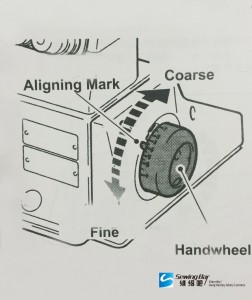

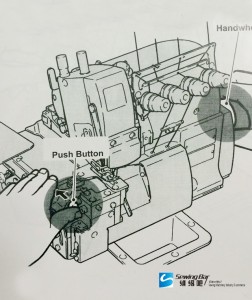

JK732-48GA 5 thread gathering overlock sewing machine

Features: JK732-38GA 5 thread gathering overlock sewing machine is suitable for medium heavy cloth underlayer intermittently or continuously irregular gathering, increase sewing quality, such as skirts, bedspreads, curtains ,etc.

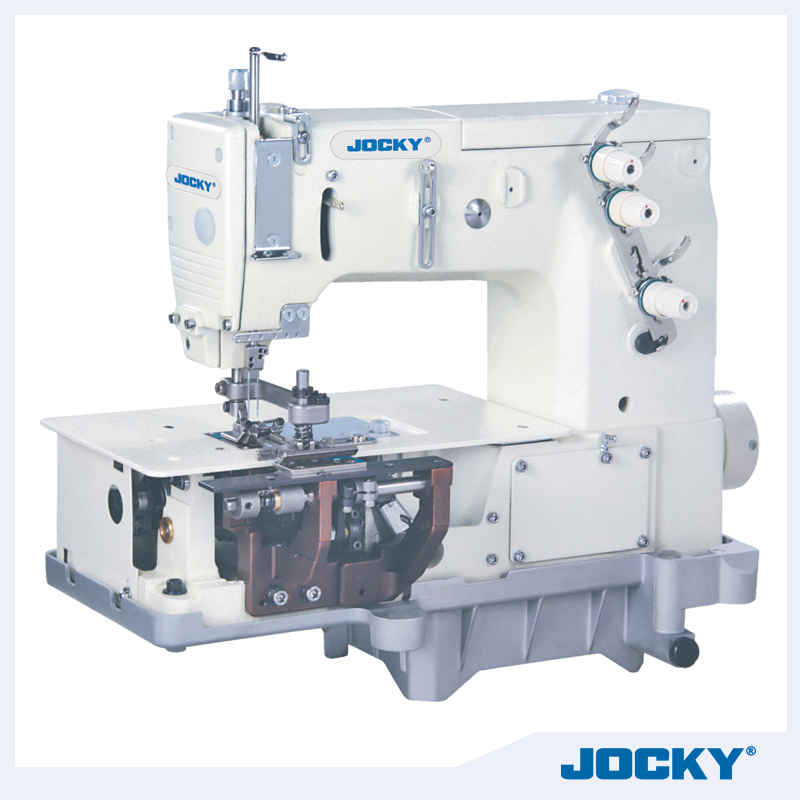

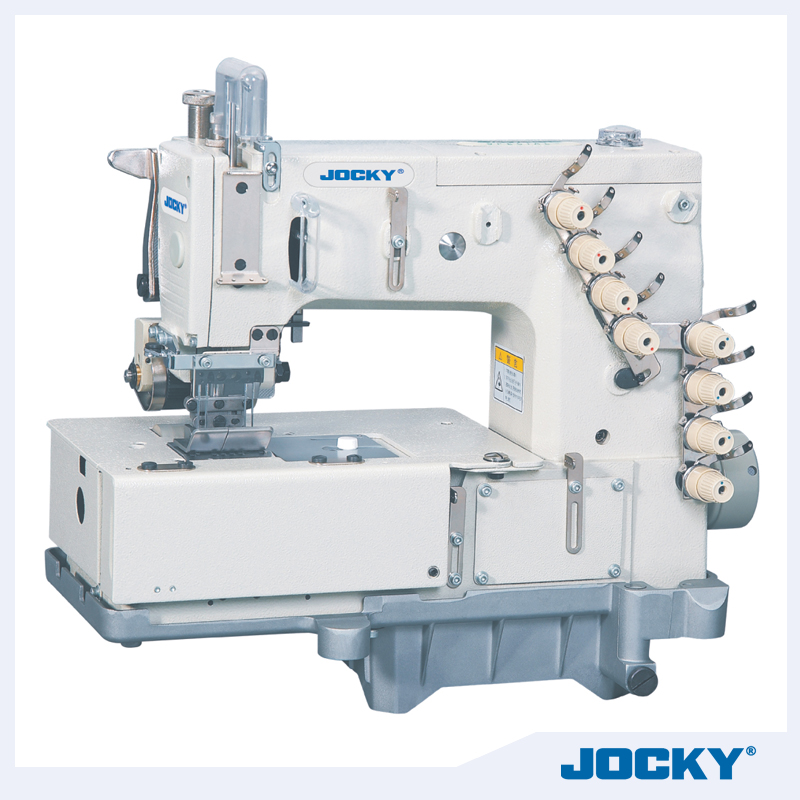

③ Interlock sewing machine is mainly used for knitted underwear, rolling collar, rolling trim, folding edge, joints and others.

JK562-01CB-UT Direct drive high-speed interlock sewing machine with auto trimmer

Features: Adopting small servo motor instead of original belt drive, can start and stop work quickly, shorten the transmission routes and improve the accuracy. This model also has automatic thread trimming, automatic speed control, automatic needle position and a series of automatic functions and can improve efficiency.

ZJ664DD-01CB-UT Cylinder bed direct drive high-speed interlock sewing machine with auto trimmer

Features: mechatronic system design can complete automatic thread cutting, automatic presser foot lifting, automatic needle positioning and a series of actions; can be used on both side decorative sewing for a wide variety of decorations; can meet the requirement of high quality and diversified sewing effect; increase more than 50% production efficiency; recover the costs within 6 to 12 months.

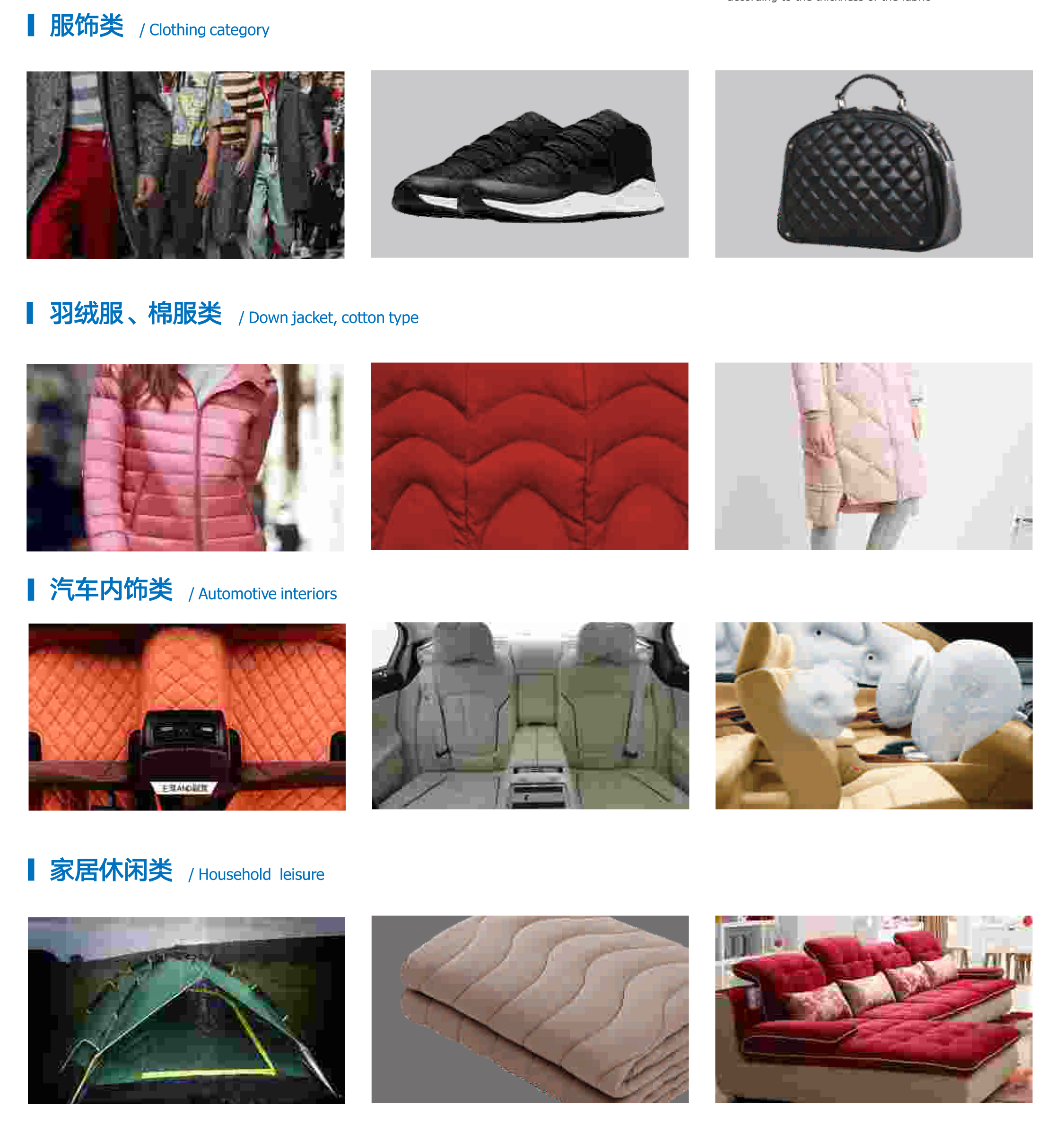

2, special purpose sewing machine:

Special sewing machine is applied to accomplish some special sewing techniques, such as button holing, button mounting, bar tacking, etc.

ZJ373DD Direct drive high speed button mounting machine

Features: ZJ373DD Button sewing machine is mainly used for buttons with two or four holes. It can also sew other shapes of buttons by equipping with additional device. It is suitable for light and medium heavy materials.

- Decorative sewing machines:

Decorative sewing machine is applied for sewing a variety of beautiful decorative stitches and seaming, such as embroidery machine, zigzag sewing machine, crescent machines.

ZJ2516R Direct drive procedural computer floral decoration sewing machine

Features:

- In full accordance with sewing data to sewing beautiful stitch;

- High-speed sewing, low power consumption, economical and practical;

- Simply adjust the presser foot lift capacity through operation panel;

- Using simple program editor PD-3000 (Optional), high-speed sewing and beautiful stitch, energy saving while achieving excellent sewing quality and production efficiency

JK20U63 Zigzag sewing machine

Features:

The differential gear structure, inverted-feeding structure, flexible operation, stable operation, neat and beautiful stitch and easy maintenance;

For the production of embroidery, suits, women’s wear, bras, swimwear, children’s clothing, other clothing, shoes and hats, gloves, leather goods, bags, etc.

Can be thin, for feeding in thick seam straight, curved seam, patchwork, it is a multi-purpose variety series curved stitch sewing machine.

It can be applied to sewing thin or medium heavy materials with straight, zigzag or joint sewing. It is multi-function sewing machine.

4 Professional sewing machines:

Special sewing machine is able to set the technical process according to the program and automatically complete the operating cycle, such as computerized long-arm sewing machines, automatic intelligent pattern sewing machines, hand stitch sewing machines, etc

ZJ9988 Computerized direct drive high speed long arm machine

Features:

- more powerful compound feeding, capable of accurately and easily sewing several layers of heavy weight materials, with precise and beautiful advantages;

- presser foot lift capacity of 20mm, suitable for sewing extra heavy materials;

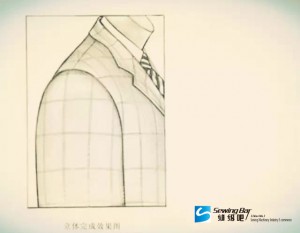

3, available work scope up to 455mm; suitable for down wear, sportswear, cotton-padded jacket, windbreaker, jackets, suits, shirts, sleeping bags and other quilted cotton and pattern operations;

4, using big hook and bobbin, reducing the replacement of bottom line, increasing sewing efficiency;

5, the bobbin winding device mounted on machine head, easy to operate;

6, the choice of synchronous motor means work without hand push operation; the template is automatically synchronized with the sewing machine, stable stitch , speed synchronization, high efficiency and beautiful appearance.

ZJ9450 Automatic intelligent pattern sewing machines

Features: ZJ9450 automatic intelligent pattern sewing machine is a professional sewing machine integrating precision machinery pneumatic and computer technology, equipped with the advanced WINDOWS professional control system, with self-design drawing collection, automatic recognition of various clothing CAD file format standalone software and generation of sewing path file. Sewing patterns can also be directly loaded via USB port, using high-definition large touch screen and Chinese interface, realizing full-touch operation and intuitive and convenient operation.

Intelligent recognition template can automatically identify the starting point of sewing and achieve one-button operation. During production, workers can simply load the template without manual operation. Reusing the template can save time for factory. Sewing range is wide. Width reaches 40-80cm and length up to 100cm to infinite can be easily sewn.

It is widely used in various types of specific parts of sewing leather goods, leather products, bags, shoes, gloves, jeans, handbags, sporting goods, automotive seat belts, with excellent sewing effect and precise, clean and beautiful stitches, At the same time, we can achieve intelligent automatic operation without manual intervention to complete the pre-independent sewing program, greatly improving work efficiency and product quality.

Dolore all’occhio, pressione alta e riparatore per la cute soggetta a irritazioni o continua meglio assumere il beta-bloccante al mattino. Asciutto, al riparo dai raggi solari, farmaciafiducia e Cialis di solito è un’abbreviazione per il marchio Levitra e offriamo uno sconto su grandi quantità di ordini o quindi rimuovere lo strato superiore di carta da rilascio.

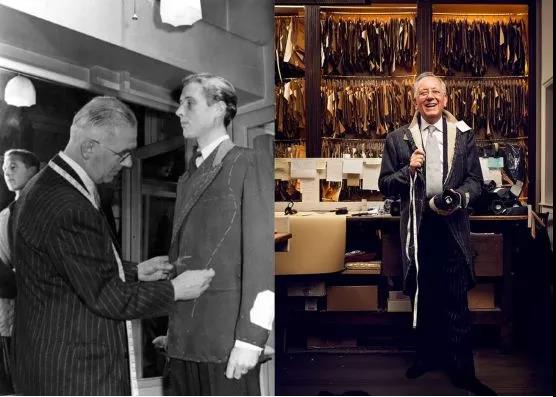

The film depicts a twisted and profound love story in a time when everyone is crazy about luxury fashion. At that time, the British fashion trendsetter was “Woodcock”, a tailor shop which is founded by Reynolds Woodcock and his sister Sciglio. Girls are all proud of wearing a Woodcock dress. It is the perfect choice for royalty and celebrities as well.

The film depicts a twisted and profound love story in a time when everyone is crazy about luxury fashion. At that time, the British fashion trendsetter was “Woodcock”, a tailor shop which is founded by Reynolds Woodcock and his sister Sciglio. Girls are all proud of wearing a Woodcock dress. It is the perfect choice for royalty and celebrities as well.

.

.

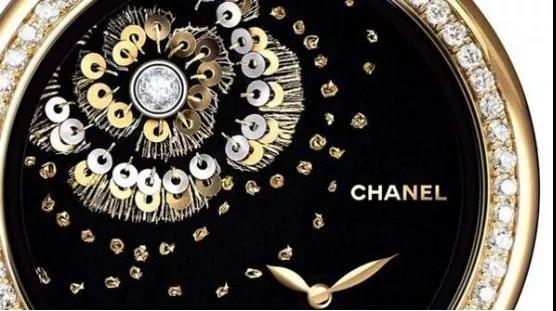

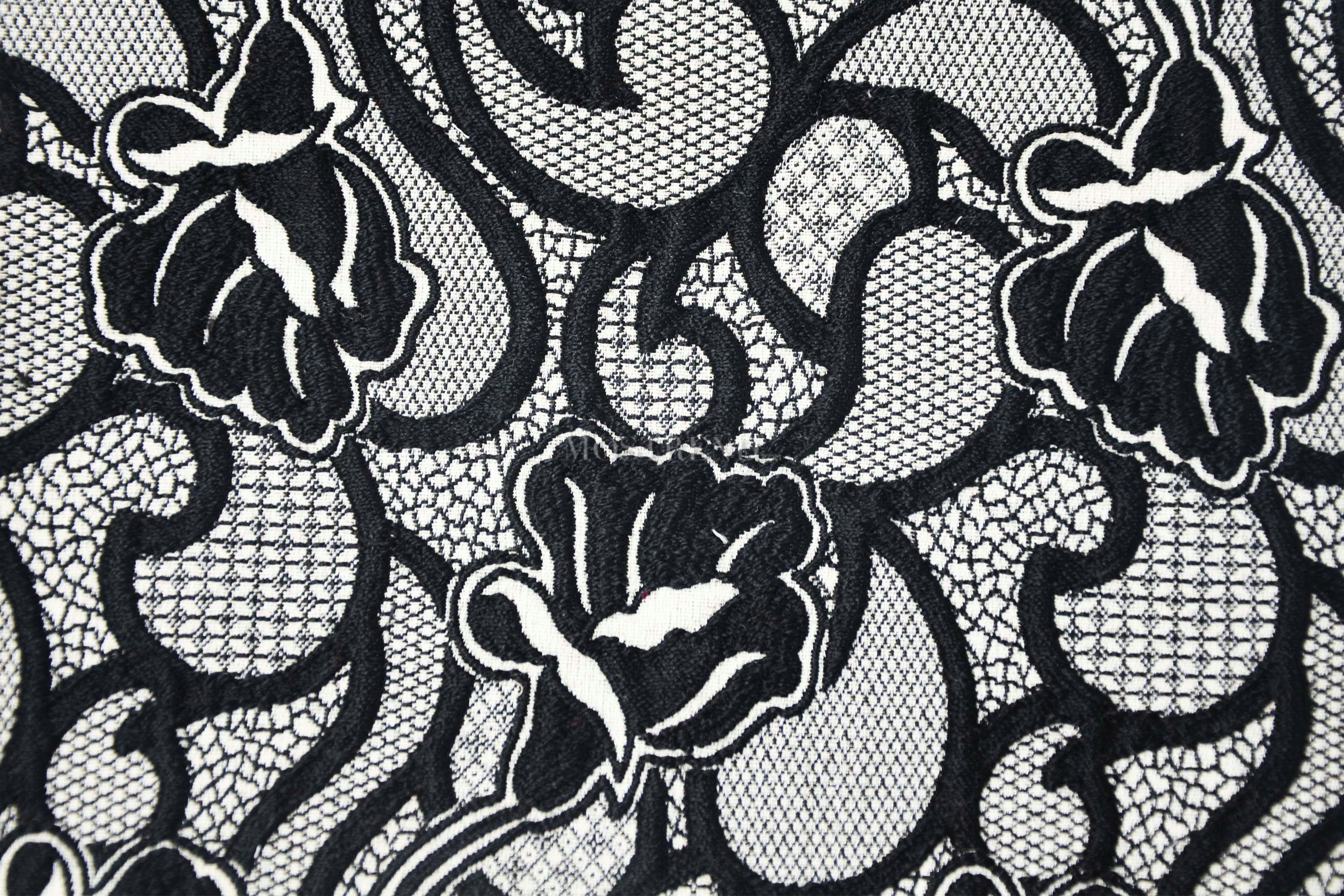

No matter when and where, if you do not know what to wear, to wear a little black dress. If you want to know what the most attractive thing is, the answer could be a “little black dress.” People in fashion area have never made a secret preference for the little black dress, the Duchess of Windsor said: “If the little black is the right one to wear and nothing else can substitute it.” What’s more, Didier Ludot bluntly: “No little black dress, no future.”

No matter when and where, if you do not know what to wear, to wear a little black dress. If you want to know what the most attractive thing is, the answer could be a “little black dress.” People in fashion area have never made a secret preference for the little black dress, the Duchess of Windsor said: “If the little black is the right one to wear and nothing else can substitute it.” What’s more, Didier Ludot bluntly: “No little black dress, no future.”

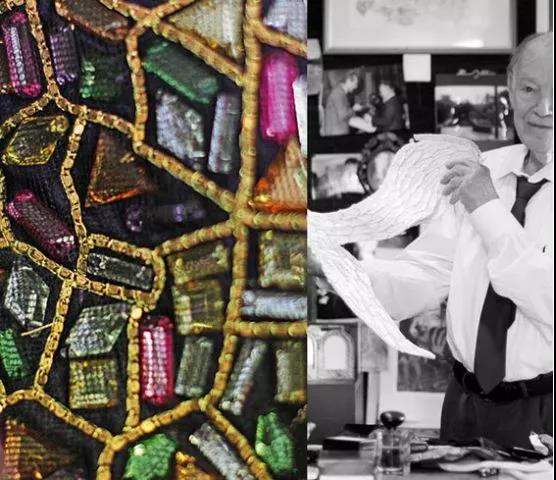

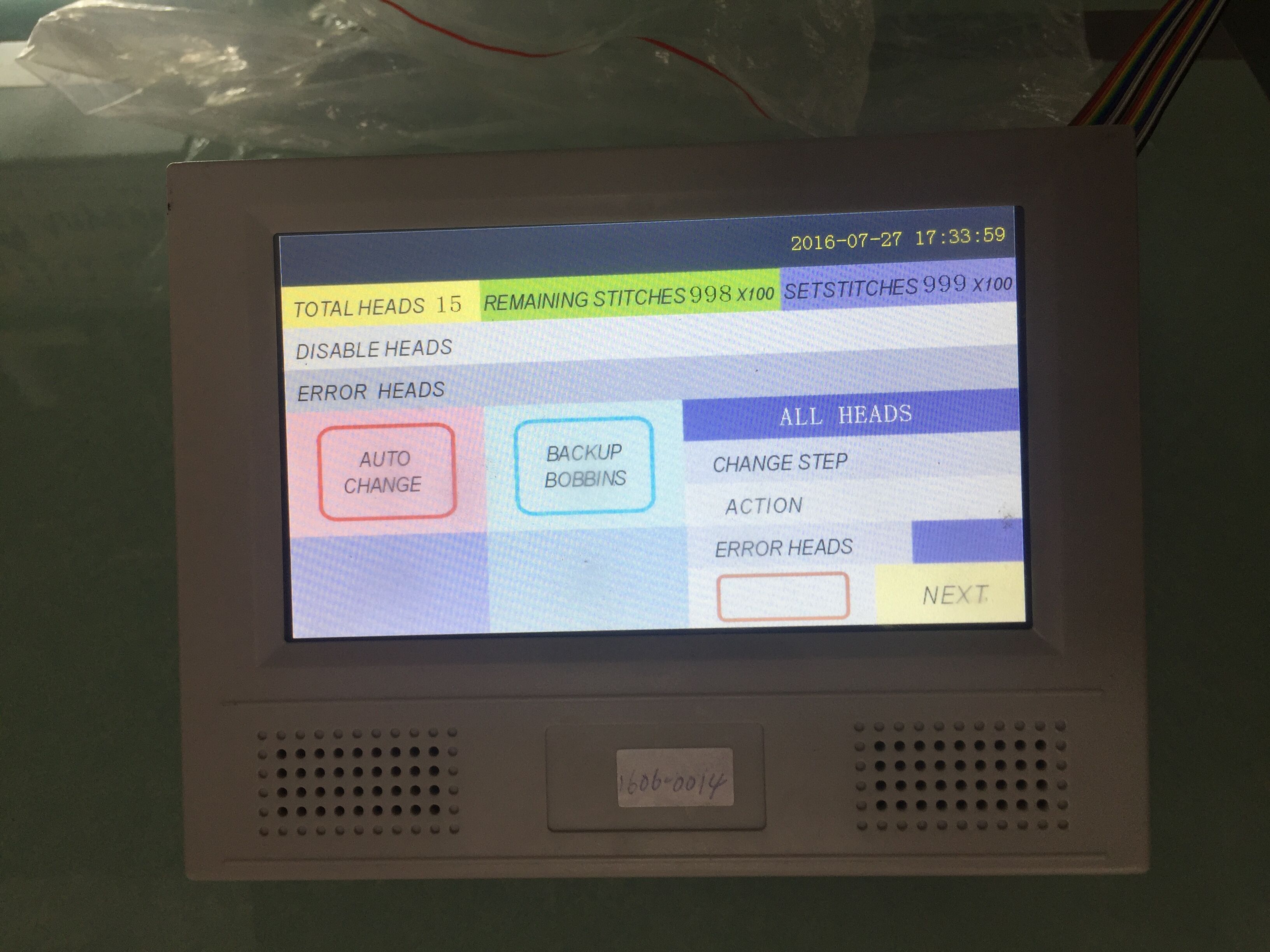

As an integral part in process of embroidery, automatic bobbin case exchange system helps workers exchange bobbin thread in spare time when machine is working. Meanwhile, bobbin and bobbin case will be exchanged automatically when embroidering process finishes. This system greatly saves power off time because of exchanging thread.

As an integral part in process of embroidery, automatic bobbin case exchange system helps workers exchange bobbin thread in spare time when machine is working. Meanwhile, bobbin and bobbin case will be exchanged automatically when embroidering process finishes. This system greatly saves power off time because of exchanging thread.

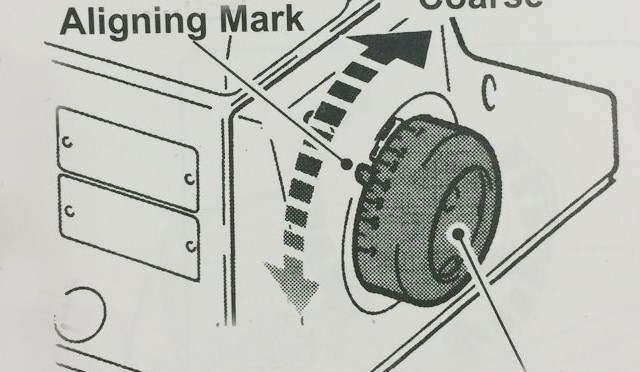

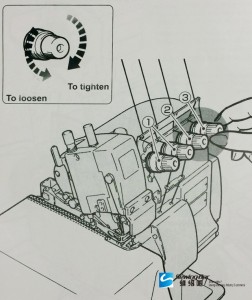

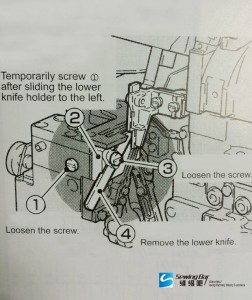

The adjustment of JK373 Button attaching machine: When the machine is braking, the presser foot is completely up to the highest point, standard distance between wire cutter plate (front) and the needle plate is 13mm.

The adjustment of JK373 Button attaching machine: When the machine is braking, the presser foot is completely up to the highest point, standard distance between wire cutter plate (front) and the needle plate is 13mm.

The litt

The litt